4927 St. Croix Avenue, Golden Valley, MN 55422

For more information, call (763) 208-8259

Product Development and Equipment Design

The extent of our experience over past years includes something beyond 300++ products or product variations. We would like the opportunity to share this experience with you. We are prepared to put together a design team to provide a solution to virtually any original product development issue or product improvement effort that you can come up with.

"Give me a feature, make sure it doesn't break down, and I'll sell as many as you deliver."

Paraphrase of Mr. Duke Newton, Zahn Equipment Co. of Tampa, Florida, Toro Distributor. Above statement made while educating Toro engineers on the real world of equipment design, concerning a mower on a Tampa golf course fairway. "Feature" means some real or genuine advantage that your product has over all your competition and that the sales force can clearly point to or demonstrate. All else is fluff.

If you would like more information on any of the following items, please click it.

The following eight items (projects) were conducted as direct employee of Toro. If you have owned Toro consumer equipment, you have probably benefited from our design efforts, either as employee, or consulting office to Toro.

PROJECT DESCRIPTIONS

ALGORITHMS, MATHEMATICAL We are capable of creating mathematical models of most physical, or mechanical/electrical situations. We then convert these into a (almost) real time computer model that allows you to vary the inputs at will. For example, you could vary the ground speed of a vehicle or water speed of a boat. The computer animation would then follow your inputs and could be constructed so as to demonstrate if a boat would porpoise at a particular speed, position of the propeller with respect to the bottom of the boat, the thrust, the wetted surface, the beam, the length, etc.

The program could then vary the above physical characteristics while the boat is moving through the water. In other words, we enable you to "drive" the boat on the computer, follow the action on the screen, and see the results as movable graphics. What's most interesting, is that a test driver of a full size prototype boat can control only the steering wheel and the throttle. With a well done computer algorithm, the test driver would control not just the steering wheel and the throttle. He would also control the hull shape, width, length, center of gravity, engine characteristics, or thrust, propeller position, passenger load and position, and any other characteristic one might choose. This would be a very real interactive design tool for maximizing performance of any particular craft.

AUTOMOTIVE HEATER Thermodynamic (heat transfer) investigation and analysis of the effect of restrictions in water flow to various automotive heaters for various input water and air conditions. Formal report. www.phillipsandtemro.com

BENCH GRINDER Electric bench grinder developed from original concept sketches for shape and visual by in-house industrial design group. Performed all mechanism, electrical wiring, internal function for motor and fan position design and planning. Provided full solid model (computer file) and coordinated prototype from fused deposition model. www.blackanddecker.com

BUBBLE SWITCH DESIGN PARAMETERS This project consisted constructing mathematical models of a number of typical bubble switch configurations. One of our conclusions was that the sharp edge where the bubble met the flat surface was causing very high (destructive) stresses in the PC laminate material at that point. Also, we were able to determine that the the problem was worse or most aggravated for the thicker materials.

CD PRINTING MECHANISM DESIGN AND/OR REVIEW Paper analysis of system for fabrication of compact disk printing system. Developed concept(s) for cost reduction and streamlining of system and reduction of number of parts. A variety of options were looked at. Overall effort resulted in about 25% cost reduction of the basic system. We believe other, more radical changes will amount to even greater cost reductions with an overall increase in performance. www.rimage.com

CHAIR WALKER This effort consisted of working with a 55 year old woman woman who had been crippled since she was 15. It was then that her father built her a unit that allowed her to get about with a walker that also served as a chair. We were approached because her 40 year old unit just plain wore out. The unit we provide allowed her to carry her radio, her knitting, magazines and newspapers. We also provided hand brakes for the wheels to allow her to support herself from it in a stationary mode.

CHEESE MIXING DEVICES Designed and developed full (6-unit) line of cheese mixing devices (could be used for mixing most any product) for essentially breaking up clumps of product and mixing various components.

COAL AUGER TRANSMISSION Design, coordination and construction of three variations of coal auger driving transmissions (client conceptions) including a complete formal load analysis of all components. (Max capacity 25,000-ft. lbs. - very heavy duty.) Formal report submitted. (United States Bureau of Mines)

COMPRESSION RELEASE System for two cycle engine compression release. Automatic compression release actuation upon pulling on starter rope. www.toro.com

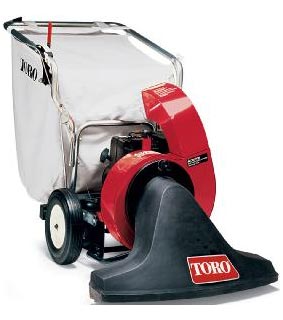

COOLING FAN

DESIGN We were requested to deal with a serious overheating issue with a potentially new yard vacuum/blower for the company's line of consumer products. We designed and fabricated a uniquel double-sided motor

cooling fan, with fan/motor housing configuration that lowered temperature inside the housing by nearly 18 degrees Fahrenheit as compared to the original configuration. This involved complete

air flow experimental and numerical analysis of the air flow and shapes of

the duct(s). We believe the fan and ducting system we developed for this effort

is still used, essentially unchanged, in all of Toro's later yard vacuum/blowers. We also introduced Toro to the concept of the super efficient airfoil

shaped fan blade. www.toro.com

Fahrenheit as compared to the original configuration. This involved complete

air flow experimental and numerical analysis of the air flow and shapes of

the duct(s). We believe the fan and ducting system we developed for this effort

is still used, essentially unchanged, in all of Toro's later yard vacuum/blowers. We also introduced Toro to the concept of the super efficient airfoil

shaped fan blade. www.toro.com

ECG GROUNDING ELECTRODE CLAMP Design and analysis for ECG grounding electrode clamp for use with ECG heart monitoring equipment. This was a totally new concept which represents quite an improvement over anything now on the market. Formal report.

ELECTRONIC ASSEMBLY STATION This unit was created to perform the operation of crimping the connectors onto the flexible tab ends of printed circuits in order to eliminate a carpel tunnel tunnel problem before it degenerated into a much more serious situation. In addition, it allowed the process speed to be increased by over 100%.

ELECTRIC CAR POLISHER Electric car polishing device for major manufacturer. Prototype used as model for Asian production. This project amounted to the design, fabrication of multiple prototypes, preliminary testing of prototypes, and creation of formal drawings. Completed unit was boxed, and shipped to client. www.blackanddecker.com

ENGINE GENERATOR

Complete engineering and industrial design

for enclosed 4000 watt, 110 volt engine/generator set including styling, prototype

construction, cooling air flow, ducting, UL investigation. Unit

designed for inclusion into mobile homes and similar vehicles.

www.wincogen.com

ENGINE GENERATOR

Complete engineering and industrial design

for enclosed 4000 watt, 110 volt engine/generator set including styling, prototype

construction, cooling air flow, ducting, UL investigation. Unit

designed for inclusion into mobile homes and similar vehicles.

www.wincogen.com

ENTERAL

DELIVERY SYSTEM Research effort to come up with various optional

methods to pump medicinal or nutritional fluids into patient during various

hospitalization situations. Involved r eview of existing systems,

brainstorming of optinal systems, and presentation of best options to client

(Sandoz Nutrition). www.sandoz.com

eview of existing systems,

brainstorming of optinal systems, and presentation of best options to client

(Sandoz Nutrition). www.sandoz.com

FAIRWAY MOWER BAGGING SYSTEM Concept development and construction of fairway mower bagging system which ultimately became Toro's standard system (original concept by client's ex-department director). Effort included design and construction of drive components, blowers, chute, grass container, power connection system etc. Final production was (is) very similar. www.toro.com

FAIRWAY MOWER VIRTUAL PIVOT This concept was originated exclusively by Mr. Berner of this office. It consisted of a couple pairs of pivoting links which, in turn, created a "virtual pull point" at any desired location. The virtual pull point could even be located below the surface of the ground when the cutting unit was generally level. This configuration reduced or eliminated cutting unit "bobbing" - a visible "ripple" over the cut grass surface. We created a computer animation that allowed the linkage to be pre-calculated and tested prior to fabrication. www.toro.com

FLYING HEAD ACTUATOR Flying head actuator for simultaneous writing of information on stacked multiple computer discs - complete system concept and design. Devised system to allow individual or simultaneous actuation. System was ultimately incorporated into the disk quality assurance system at IBM's Rochester facility. (IBM Rochester). www.ibm.com

FOLDING HANDRAIL FOR ELDERLY AND HANDICAPPED As part of a study involving the negotiation of stairways for the elderly and handicapped, a concept was further developed for assisting the individuals to more safely climb up or down stairs. The device essentially amounts to a walker which is affixed to one side of a stairwell and makes it possible to secure one's position all the way up and all the way down a stairway so as to avoid the head-over-heel fall. This is presently installed in about 50 - 55 homes around the Twin Cities metropolitan area. As result of this work, and a couple of other projects, we have gained considerable expertise in the whole area of assistive technology related to safely moving people. We are also looking to license the involved patents to an interested manufacturer. U.S.Government

FOOD DELIVERY CART - HOSPITAL This effort came about as result of a review of the food delivery system at one of the local hospitals (HCMC). The object was to see if we could come up with a better system for hooking individual food carts onto an overhead monorail that was already in place. The existing system required a combination of high strength and agility to hook the carts on to the overhead rail. We came up with a system for accomplishing this by designing a new food cart with the mechanism for hooking built into the roof. The initial lift force was applied close to the center of gravity of the cart. Simultaneously, the lifting hooks were secured by a snap in (bayonet) lock. We built a quarter scale model unit that allowed us to work out bugs and demonstrate the concept perfectly. www.hcmc.org

FUSED DEPOSITION

3D MODELING - POSITIONING SYSTEM

FUSED DEPOSITION

3D MODELING - POSITIONING SYSTEM

GARDEN CULTIVATOR Developed garden cultivator based upon patent by German inventor which involved use of counter-rotating tines to both cultivate and propel unit in a variety of soil conditions. (Black & Decker). www.blackanddecker.com

GASOLINE CONTAINER WITH BUILT IN PUMP Design for a gasoline container with a built in hand pump system. This included complete design plus drawings and production cost estimate for the optimal configuration. This included blow molded parts and pump components. www.j-markproducts.com

GOLF CLUB DRIVER HEAD DESIGN This project consisted of taking client's idea for a golf club driver head configuration, constructing appropriate sketches and drawing(s), prototyping it and finally constructing a set of metal heads for trying out. The process was then repeated for three or four optional configurations. Private Investor

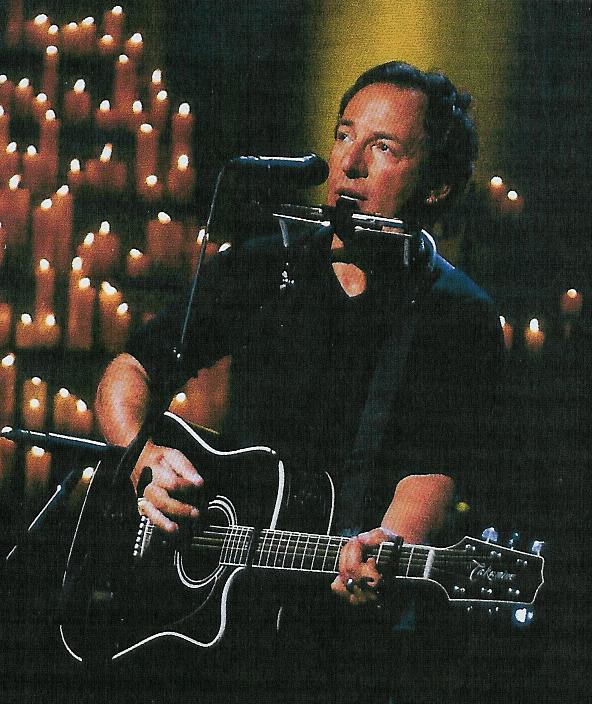

GUITAR CAPO

A capo is a device used by

guitar players, professional and amateur,

that clamps on the strings of a guitar and

raises the pitch of all the strings at once. The famous Kyser Capo is based upon a

concept generated by John Berner as a take-off on a snap clothes pin. The patent was

subsequently licensed to the Kyser Music Company of Dallas, Texas. It has been seen

and used on every major variety show in the country for the past 10 years. Among its

original users were Johnny Cash, Dolly Parton, Bruce Springsteen and later

on, two or three hundred

other rock and country singers.

www.kysermusical.com

that clamps on the strings of a guitar and

raises the pitch of all the strings at once. The famous Kyser Capo is based upon a

concept generated by John Berner as a take-off on a snap clothes pin. The patent was

subsequently licensed to the Kyser Music Company of Dallas, Texas. It has been seen

and used on every major variety show in the country for the past 10 years. Among its

original users were Johnny Cash, Dolly Parton, Bruce Springsteen and later

on, two or three hundred

other rock and country singers.

www.kysermusical.com

HARD ROCK BIT TESTING MACHINE Design and supervision of construction of a hard rock bit testing machine. This was used for testing of mining bits by the United States Bureau of Mines. This involved extremely high forces. (United States Bureau of Mines)

HEAVY DUTY AUTOMOBILE JACK Concept design to working prototype of simple unit to lift 1/2 of a vehicle for rotating tires, etc. Including stress analysis. www.j-markproducts.com

HEDGE TRIMMERS Developed largest Black & Decker hedge trimmer as extension of the original line. Provided complete line maintenance and production support for four other units of the line.

HIGH SPEED CLUTCH/BRAKE Analysis and design recommendations for high-speed clutch/brake system design. This included analysis of the problem(s) associated with brake component failure before clutch component failure - an unsafe condition. This particular design study involved the comparison of the capability of the brake system with the capability of the clutch system by way of a Weibull analysis. Report. www.toro.com

INSULATOR CARRIER FOR MOBILE SUBSTATION Structure mounted to rear of mobile substation semi-trailer to carry the large, high voltage (17,000 volts) emergency power insulators. Featured built in crank system which could be actuated from the ground by one person to move outside insulators away from center to provide 8-foot separations. www.xcelenergy.com

JOGGING BUGGY REVIEW AND DESIGN Initial project involved review of problems concerning Taiwan production of jogging buggies. Participated in discussion with the manufacturer. Later on worked with developing device for attachment of buggy to a bicycle (patented). TRI Industries, Edina MN

LAWN AND GARDEN ELECTRIC APPLIANCES This was work performed as group leader of eight people employed by Black & Decker. www.blackanddecker.com

GARDEN CULTIVATOR Developed garden cultivator based upon patent by German inventor which involved use of counter-rotating tines to both cultivate and propel unit in a variety of soil conditions. (Black & Decker).

SIDEWALK EDGER(s) Developed largest of Black and Decker’s sidewalk edgers for edging and trimming in various yard situations. Provided full line maintenance for four other lines.

HEDGE TRIMMERS Created largest Black & Decker hedge trimmer as extension of the original line. Provided complete line maintenance and production support for four other units of the line.

STRING TRIMMERS The original Black & Decker string trimmer was created through a couple of people in my group. In this capacity, and because we were the first company to seek U.L. approval for string trimmers, I was also heavily involved in writing the first U.L. specification for string trimmers.

LOUVERS NON-FREEZING This concept was developed, prototyped and demonstrated in response to the need to prevent louvers for sugar beet barns from freezing up in Minnesota's cold winters. Our concept worked beautifully. Subsequently we became aware that this was also a problem with turkey barns. However, in this case, multiple thousands of turkeys could be lost.

MINNOW DISPENSING SYSTEM Review of design for a coin operated minnow dispensing system. Major problem was the minnows did not seem to last as long as they should. We identified a problem with the material in one of the components the minnows were exposed to. Also recommended improved aeration system. Part list and cost estimates were also constructed. Private Investor

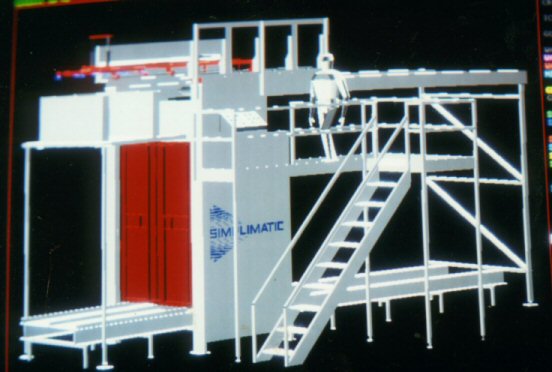

PALLETIZING EQUIPMENT Review of design and structural

configuration of a complete line of palletizing equipment for soft drink

cans. This is large equipment - i.e. 12-15 ft high, 50-60 ft long,

10-12 ft wide. The

object was a redesign to streamline the general appearance of the line, yet

avoid any compromising of the structural integrity and function of the equipment.

Graphics were developed around our 3D computer models of the machines. The

major industrial design part of this effort was conducted by Mr. Mario Fernandez

www.mariofernandez.com . He also developed a suggested new logo and incorporated it

into the equipment renderings. Our efforts also involved review of OSHA issues.

www.simplimatic.com

PALLETIZING EQUIPMENT Review of design and structural

configuration of a complete line of palletizing equipment for soft drink

cans. This is large equipment - i.e. 12-15 ft high, 50-60 ft long,

10-12 ft wide. The

object was a redesign to streamline the general appearance of the line, yet

avoid any compromising of the structural integrity and function of the equipment.

Graphics were developed around our 3D computer models of the machines. The

major industrial design part of this effort was conducted by Mr. Mario Fernandez

www.mariofernandez.com . He also developed a suggested new logo and incorporated it

into the equipment renderings. Our efforts also involved review of OSHA issues.

www.simplimatic.com

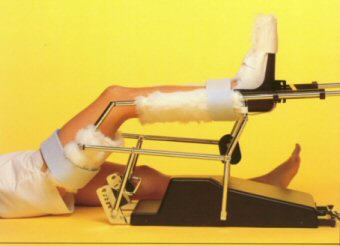

PASSIVE MOTION

EXERCISE MACHINE Design of machine for

providing motion for a leg recovering from knee surgery. Project included initial

simulation on computer, design of linkages, propulsion system, sourcing components and

building of various stages of prototype (EMPI). Subject of article in

Design News magazine. Led to Minnesota's Seven Wonders of Engineering Award.

Follow-up project to this was analysis of linkage loads.

www.empi.com

PASSIVE MOTION

EXERCISE MACHINE Design of machine for

providing motion for a leg recovering from knee surgery. Project included initial

simulation on computer, design of linkages, propulsion system, sourcing components and

building of various stages of prototype (EMPI). Subject of article in

Design News magazine. Led to Minnesota's Seven Wonders of Engineering Award.

Follow-up project to this was analysis of linkage loads.

www.empi.com

PRODUCTION DESIGN FOR RIGHT ANGLE REDUCER Complete design and analysis for high volume production of right angle gear reducer assembly. Report included analysis of AGMA ratings and recommendations. www.toro.com

PROJECT RETURN ON INVESTMENT ANALYSIS This was a computerized system for inclusion of all the company's engineering projects into an overall analysis of their combined return on investment. This was necessary because costs assigned to various programs were regularly based upon whimsical (fast and loose USWAG) figures than on factual data. In addition, specific engineers recognized that, due to erroneous tax treatment, new product programs were being unfairly compared to alternative investments. This effort had the effect of putting cost estimates on a more legitimate, professional, footing. (Toro) www.toro.com

PROTOTYPE SHOP Organized Black & Decker's original prototype shop dedicated exclusively for use of the Lawn and Garden group. The object was to allow engineers and designers to construct very rough demonstration type models of concepts. This was to compensate for the extreme difficulty of obtaining that type of support from the main model shop and its competing demands. Partly as result of this, the Lawn and Garden group became one of the top performers (the top?) within the B&D engineering operation. www.blackanddecker.com

SIDEWALK EDGER(s) Developed largest of Black and Decker’s sidewalk edgers for edging and trimming in various yard situations. Provided full line maintenance for four other lines.

SKY LIGHT ACTUATION AND CONTROL MECHANISM We developed a control for a window operator to control incremental movement of a window. The control moved the window to an open or closed position. A system was set up for determining when multiple motor drives moved predetermined distance. This was set up to make sure that if one motor outran the others by a small amount, it would stop and wait for the rest. Once all the rest caught up, they would stop and wait till the slowest motor caught up. Then they would all proceed. The process would then repeat. However, the total increment was so small that the overall motion appeared to be very smooth. Truth Hardware www.truth.com

SNOW THROWER - SINGLE STAGE ELECTRIC Designed and developed single prototype of single staged electric snow thrower based upon utilizing the remarkable low speed lugging power of the universal electric motor. Propriety experimental

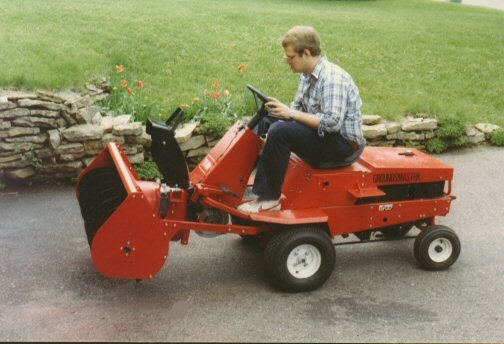

SNOW THROWER ATTACHMENT FOR VEHICLE

Design,

fabrication, and

assembly of 2-3 prototypes of 2-stage snow thrower attachment for Toro institutional

application. Unit probably still in production in revised form. When in-house

conflicts kept project coordinator from meeting his commitment to provide fabrication of

the components, we saved the day by organizing, planning, constructing

components, and

assembling the complete units ourselves.

www.toro.com

SNOW THROWER ATTACHMENT FOR VEHICLE

Design,

fabrication, and

assembly of 2-3 prototypes of 2-stage snow thrower attachment for Toro institutional

application. Unit probably still in production in revised form. When in-house

conflicts kept project coordinator from meeting his commitment to provide fabrication of

the components, we saved the day by organizing, planning, constructing

components, and

assembling the complete units ourselves.

www.toro.com

STRING TRIMMERS Developed original Black & Decker string trimmer, through a couple of people in my group. In this capacity, and because we were the first company to seek U.L. approval for string trimmers, I was also heavily involved in writing the first U.L. specification for string trimmers. It was submitted through cooperation with, B&D safety specialist and long time U.L. Board member.

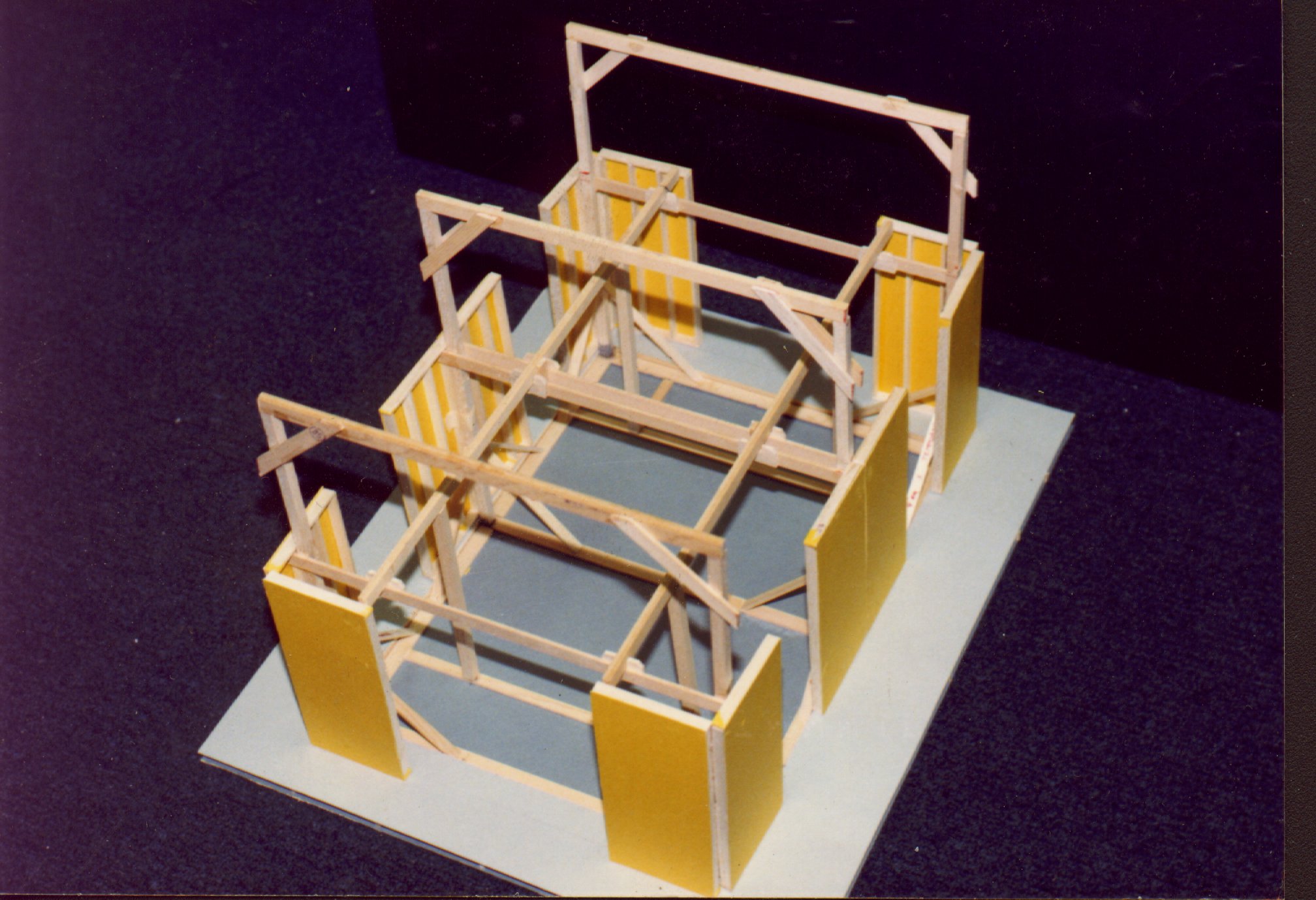

TRADE

SHOW DISPLAY Design and supervision of construction of traveling

trade show display. This 20' by 30', two story, display had to be designed in such

manner as to be safe and stable all the way up and all the way down.

Therefore, we not only had to design it, but we also had to carefully spell

out how it was to be assembled and disassembled. The system traveled

around the country for at least a couple summers.

www.cornelius.com

TRADE

SHOW DISPLAY Design and supervision of construction of traveling

trade show display. This 20' by 30', two story, display had to be designed in such

manner as to be safe and stable all the way up and all the way down.

Therefore, we not only had to design it, but we also had to carefully spell

out how it was to be assembled and disassembled. The system traveled

around the country for at least a couple summers.

www.cornelius.com

ULTRASOUND SUPPORT ARM We were asked by the ARIC study group (Athloslcerosis Risk in Communities) to develop a mechanism that would eliminate the serious discomfort felt in the arms of the technician operating the ultrasound device after a full shift of lifting and holding the sensor. Multiples of these were designed and made for North Memorial Hospital and a North Carolina hospital when some of its employees spotted it on a visit to Minnesota. One of the additional benefits of this device was that it held the ultrasound transducer so still that it cut the number of photos form 4 or 5 per view, to 1 or two and cut the time in half for a typical set of procedures. These units can be constructed for any hospital in the metropolitan area. We'd be pleased to provide these units to any hospital in the metropolitan area for a very reasonable cost. North Memorial Hospital, Robbinsdale, MN www.northmemorial.com

VACUUM CLEANER FUNCTIONAL REDESIGN Developed and constructed two prototypes of vacuum cleaners according to results of a study we conducted to review the production designs. At least two of our major design recommendations were ultimately included in production units. (Kirby) www.kirby.com

VARIABLE SPEED TRANSMISSION Analysis and design commentary of infinitely variable speed transmission. Complete study of all components of drive including AGMA gear ratings. Formal report. www.polaris.com

VEHICLE TRANSMISSIONS We have experience in the original design and analysis of a variety of different vehicle transmissions. These include geared three speed transmissions, transaxles using bevel gear differentials, transaxles with spur gear differential systems, golf cars with snowmobile type variable speed transmissions, and friction drive systems (three or four different). www.toro.com

VENDING MACHINE NOISE CONTROL Investigation and recommendation for modification to cabinet for ice drink (slush) machine to achieve sound reduction. The object was to reduce the sound level to such level as to allow normal conversation to take place in the near vicinity to it. This was handily achieved by a series of changes to the materials and closure of gaps. Another interesting point here was that we liberally applied techniques learned in silencing riding lawn mowers and hand held appliances. www.cornelius.com

WIND TURBINE Preliminary studies, design, and drawings and prototype construction for roof-mounted wind turbine (augmented horizontal Darius). This effort was an investigation of the possibility of using either man made (buildings etc.) or natural structures such as low hills, tree lines etc. to augment the flow of air into a wind energy device. The results of this effort look quite promising, especially in the northern climates if the power is used to directly operate heating devices. This is because infiltration type heat loss in a structure is closely related to wind speed. Conversely, so is heat gain if provided by the wind energy device The match-up makes for interesting possibilities in northern climates and/or seashore locations. Proprietary

WINDOW BALANCE SYSTEM Window balance spring analysis and selection system for a variety of window weights and side drag situations. Developed formula for correctly sizing and optimizing spring balance system for double hung windows. Formal report. www.intekplastics.com

WINDOW FRAME REDESIGN Redesign and recommendation for a window frame system for apartment building windows which would reduce the problem of young children pushing out the screen and falling through. Redesign based on absorption of running child's kinetic energy. We were able to identify and test at least four separate systems that met or exceeded this goal.

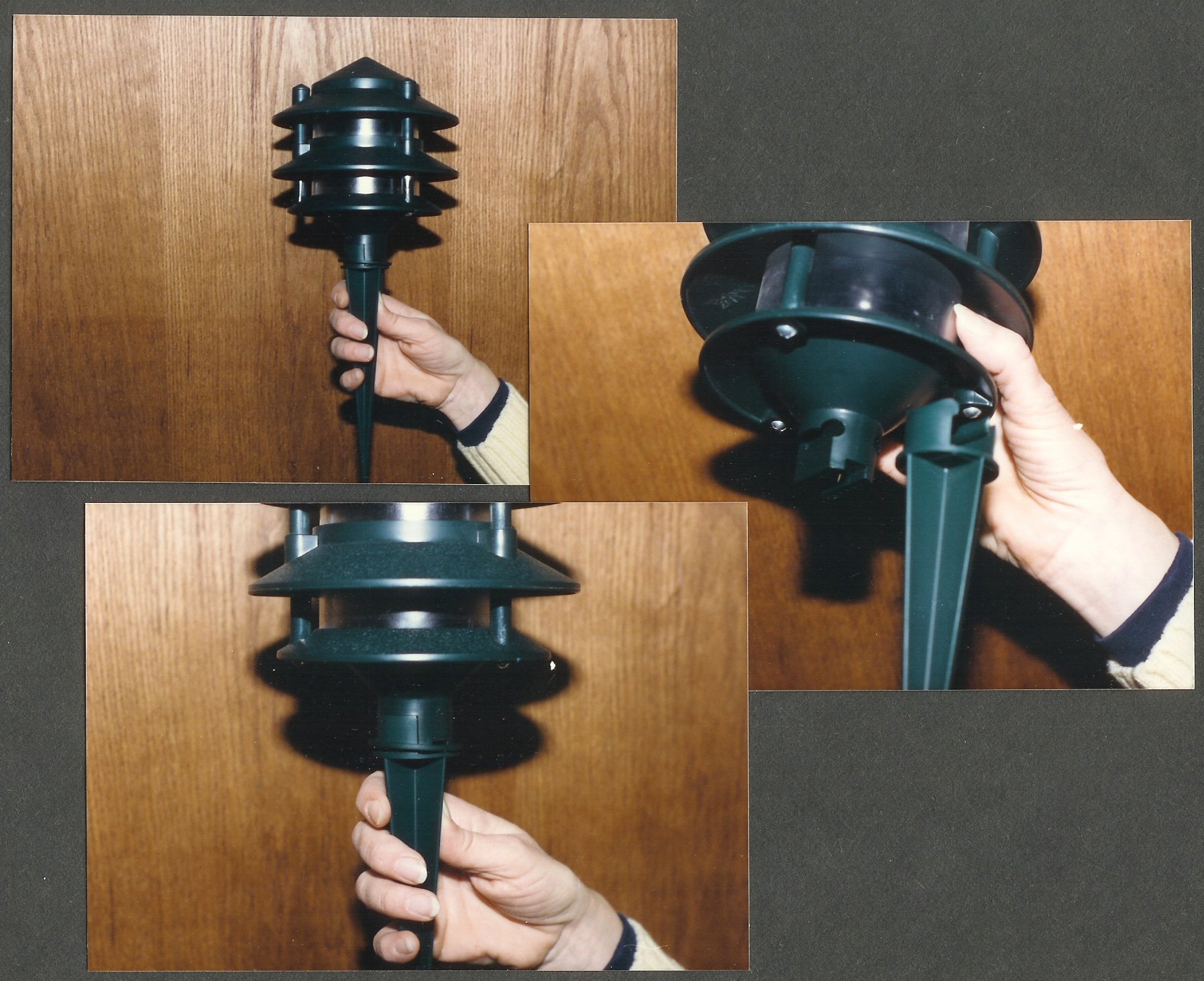

YARD LIGHT

CONCEPT Sole originators of

concept for joining cord to light for a yard light manufacturer which allowed production

of lights without infringing upon pre-existing patent(s). Project was conducted on an

emergency basis for a small electrical component manufacturer by the name of

L & L. Its manufacturing chief assigned us to this effort to overcome a patent

infringement injunction. Successful follow-up by others company led to company's (L &

L) purchase by Toro. As we understand it, the product line developed around this concept eventually became the

nucleus of Toro's Home Products Division.

www.toro.com

YARD LIGHT

CONCEPT Sole originators of

concept for joining cord to light for a yard light manufacturer which allowed production

of lights without infringing upon pre-existing patent(s). Project was conducted on an

emergency basis for a small electrical component manufacturer by the name of

L & L. Its manufacturing chief assigned us to this effort to overcome a patent

infringement injunction. Successful follow-up by others company led to company's (L &

L) purchase by Toro. As we understand it, the product line developed around this concept eventually became the

nucleus of Toro's Home Products Division.

www.toro.com

The following Toro snow projects were conducted as direct employee(s) of Toro. If you have owned Toro consumer equipment, you have probably benefited from our design efforts, either as employee, or as consulting office to Toro. This is particularly true if you own a Toro 2-stage snow thrower, riding lawn mower bagging system that allows backing up to to the pile and dumping grass without getting off the machine, or Toro's Power Curve single stage snow thrower. These efforts have included single stage snow throwers, two stage snow throwers, riding lawn mowers, walk power mowers, lawn vacuums, leaf blowers, bagging systems, and various components of all. www.toro.com

LAWN VACUUM SELF

PROPELLED (Project

Engineer) The

Toro consumer lawn vacuum was the result of a "bootleg" project. We

couldn't get appropriate drafting help, so Berner went home for two weeks

and completed the design, an arm full of drawings, plus, a 1/4 scale model,

and the traction system design. This jump-started the process by about eight

weeks. After 40 years, this exact unit is still being produced,

essentially unchanged. The ability of this unit to outperform all competition was assured because

that was our final qualification test. Its most unique characteristic

was its ability to roll (and digest) a beer can in from 6"- 8" to either side of the front snout.

We kept even airflow across the width by way of a totally original, unique,

and patentable housing configuration. The thoroughly researched and

carefully designed snout/chute system, was the most efficient on the market.

The even air flow across the width, and general reliability was easily the

best on the market for this type of product. We also believe this

may be the oldest continuous product in Toro's complete entourage of

equipment.

Toro consumer lawn vacuum was the result of a "bootleg" project. We

couldn't get appropriate drafting help, so Berner went home for two weeks

and completed the design, an arm full of drawings, plus, a 1/4 scale model,

and the traction system design. This jump-started the process by about eight

weeks. After 40 years, this exact unit is still being produced,

essentially unchanged. The ability of this unit to outperform all competition was assured because

that was our final qualification test. Its most unique characteristic

was its ability to roll (and digest) a beer can in from 6"- 8" to either side of the front snout.

We kept even airflow across the width by way of a totally original, unique,

and patentable housing configuration. The thoroughly researched and

carefully designed snout/chute system, was the most efficient on the market.

The even air flow across the width, and general reliability was easily the

best on the market for this type of product. We also believe this

may be the oldest continuous product in Toro's complete entourage of

equipment.

RESEARCH ON TORO'S SNOW PUP SINGLE STAGE SNOW THROWER (Asst. Project Engineer) Work included experimentation with various paddle/rotor materials and options Final configuration including rubber paddles and means for attaching to rotor evolved from this work.

RIDING LAWN MOWER (Project Engineer) Originator of Toro's first successful rear engine riding lawn mower. The vehicle we developed along with the bagging system (see next) was essentially the first prototype for subsequent consumer riding lawn mower that became No.1 with Consumer Reports. We originally started out with a friction drive system of our own design. That was later replaced by a standard (purchased) transmission. The cutting deck, deck drive, deck lift system, frame, and grass bagging system, were all worked out on this prototype. Excellent follow-up work, by others, followed with the result of Toro's top entry into the rear engine rider market.

RIDING LAWN MOWER

GRASS BAGGING SYSTEM

RIDING LAWN MOWER

GRASS BAGGING SYSTEM

(Project Engineer) Conceptor and developer of Toro's rear engine riding lawn mower bagging system that allowed operator to empty bag without getting off machine or shutting down engine. Others later improved upon the bag latching system. This is the concept about which American Home and Garden magazine said "Someone at Toro should get an award for conceiving and developing". Deck drive, air flow, functional hopper shape, and clamshell closure were all worked out on this unit. Vehicle we developed along with this bagging system was the first prototype for subsequent consumer riding lawn mower that became No.1 with Consumer Reports. We believe this was, in large part, due to the bagging system we developed.

(Asst. Project Engineer - as Toro employee) worked with senior level research engineer on development of approximately twelve or fourteen different variations of prototype snow throwers. The object was to investigate various concepts and settle on one to develop into a line of snow throwers. The most promising of these units were tested on Mount Revelstoke in British Columbia. Unit concept referred to as the "Snow Mill", for its ability to "mill" the hard packed snow off a driveway surface, came out of this effort. It was a quite standard configuration other than that. Another unit that showed much promise, was one we referred to as the "Snow Cone", a unit of about the same size as a standard two-stage snow thrower, but that resembled the large railroad rotary plows. Quite a number of other concepts also came from this effort. A series of reports, logs, and notes concerning all these variations were completed and left with the company patent attorney's office and, we believe, the advanced development group. We should emphasize that this work was not performed by what Toro referred to as the "Advanced Engineering" group, but was conducted as part of the regular production engineering department. In good part, as result of this program and subsequent snow equipment work (including creation of the original version of Toro's current Power Curve snow thrower) Toro came to dominate the United States snow market. The principal engineer (Mittelstadt) in charge of this project was noted for his ability and willingness to "pull out all the stops" when it came to getting positive results on a project. Every serious young engineer, or technician, who worked under him, usually picked up the trait. One of the other engineers who worked under him, ultimately became one of Toro's two most successful long-term Directors of Engineering.TWO STAGE SNOW THROWER PILOT DESIGN PROGRAM

(Project Engineer) Developed the above "Snow Mill" concept into a two-stage snow thrower pilot unit which ultimately became Toro's entry into the two-stage market. Its most unique characteristic was ability to survive a two-by-four piece of pine jammed into the front rotors without damage to the machine or shearing a key. Internal company audit concluded the pilot unit's field acceptance and performance was excellent. However, field problems, fabrication issues just about killed the concept. This was due mainly Toro production's inability (at that time) to produce a consumer product much more complicated than a lawn mower in any significant volume. The next step was to expand the pilot concept into a full three-unit line of two-stage snow throwers. However, from it, we learned a few lessons.THREE UNIT TWO STAGE SNOW THROWER LINE

(Task Team Leader and Project Engineer) This was to be the full

production design of Toro's first two

stage multi-unit snow thrower line. This was a totally new "clean sheet of paper" design.

However, preservation of the best of the pilot unit's earlier concepts was of

paramount importance. In addition, we had conducted a thorough review

of the top competitive units on the market from both a performance and a

manufacturing point of view. Based upon this, we also knew that if we

did our jobs properly, we had a very good chance at No.1 with Consumer

Reports. Therefore, this was formally established as one of the

primary goals of the program.

This was to be the full

production design of Toro's first two

stage multi-unit snow thrower line. This was a totally new "clean sheet of paper" design.

However, preservation of the best of the pilot unit's earlier concepts was of

paramount importance. In addition, we had conducted a thorough review

of the top competitive units on the market from both a performance and a

manufacturing point of view. Based upon this, we also knew that if we

did our jobs properly, we had a very good chance at No.1 with Consumer

Reports. Therefore, this was formally established as one of the

primary goals of the program.

This line was to be the first unit on the market to have all the following - -

1.) All controls on upper part of handle (Toro exclusive at this time)

2.) Self-energized traction drive in both forward and reverse.

3.) Auger tip configuration which kicked boot out rather than damage foot

4.) Utilized drum-type of auger to meter the snow and prevent stalling.

5.) Used a retractable scraper blade allowing auger to "mill" close to ground

6.) Used independent wheel clutches on the largest two units of line.

7.) Drawn to manufactured subassemblies (standard on east coast, new to Toro).

8.) Verification tests of unit's components in sand (similar to HALT process).

When the project started we had some serious issues to deal with - - -

1.) Throughout the sixties, Toro made three or four attempts to enter the snow thrower business. With one exception, the "Snow Pup", these ended ignominiously. As each of these efforts floundered, competitors such as John Deere, Simplicity, Yard-Man, and a host of others, were succeeding quite famously in the snow market. Toro looked very much like a one-trick pony so far as snow was concerned.

2.) Also, since everyone knew Toro designed and built nothing but first class equipment, the middle-management reason for the poor performance in of snow market sales was, clearly, because "Toro is a lawn mower company and doesn't belong in snow." (very close paraphrase). Therefore, it logically followed that little future funds and effort should be expended on snow equipment. Fortunately, top management and marketing knew better.

3.) The strong support group for snow equipment included two new and enthusiastic Vice Presidents of Engineering and Manufacturing - both alumni of Honeywell, strong proponents of close cooperation between design and manufacturing, definitely not fans of status quo, and intent on modernizing Toro operations. They also knew how to positively inspire young engineers. However, even they agreed that if this project didn't succeed, Toro should probably drop the snow business.

4.) A new fairway mower, the Grounds Master, was going through the company at the time. It took up all the experienced drafters and excess space in the engineering department.

5.) At that time, Toro's experience and capability with low volume complex commercial (or institutional) equipment such as the above Grounds Master, ranked somewhere between excellent and superb. This had much to do with the fact that the production lines for that equipment were located about 400 feet from the rear door of the engineering department. Consequently, troubleshooting and related communication problems were negligible - a particularly critical element for any new product line.

6.) Our snowthrower project was considered far too low in priority within the centralized drafting department to have any chance of success. Also, and partly because of the past poor sales results, snow was now considered a dead end for involvement by many (most) middle management veterans.

7.) At that time, Toro's production capability for lawn mowers and other relatively simple, but high volume, equipment was also quite good. However, its production capability with high volume consumer equipment more complicated than lawn mowers, has to have been considered shaky, at best. Past problems were due primarily to Minneapolis' inability to communicate technical information over any significant distance. This had already been graphically demonstrated with a facility Toro bought (and shed) in Springfield, Ohio. This problem had also been clearly identified and pointed out by the Vice President of Engineering, plus a number of others in the department.

8.) The production plant planned for our new snow thrower line was located in Windom, Minnesota, 150 miles southwest of Minneapolis. We anticipated the communication problems would be incredibly difficult.

One thought was to purchase a new type machine that could send a hand sketch or a small drawing over a phone line in about 8 minutes. We were overruled by recommendation of the drafting/publications department because this $3000 "gimmick" was considered not worth the cost. Those "gimmicks" are now called fax machines - the ones we have all lived by up till a few years ago. As we all know today, attempting to make a series of running change orders to a plant 150 miles away without fax or e-mail - - i.e. limited to voice communication, is virtually impossible.

Because of all the above we knew something different had to be done beyond "business as usual".

With concurrence and approval of very top management, and, in order to assure that content, accuracy, and format of the 400+ drawing package, came up to some acceptable standard, we recognized that we had to separate our project's drafting/checking function from the centralized drafting pool. To accomplish this, we hired seven contract drafters and put them in the back room of the company cafeteria - the Kitchen Gang. A new, permanently hired, layout draftsman served as Chief Draftsman and checker. This crew's prodigious output had to be considered as somewhere between excellent and superb. The main, or "top" layout, was initially constructed by the project engineer. The most senior layout man kept this top layout updated and maintained. Every evening, the project engineer reviewed and checked it for accuracy before going home. All components were checked against this constantly updated top layout. Every dimension was a calculated dimension. Using this crew, we created between 400 and 450 new drawings required for the three unit line.

In addition, we coordinated construction of fifteen prototype snow throwers, one of each size for use as preliminary test and experimental units, plus four each of each size for final design verification and marketing samples. Also, we conducted all outside sourcing of special components, vendor selection, and scheduling for production parts delivery. To facilitate this, we constructed a readable bill of materials in the form of a "Gozinto" chart that included appropriate reference to all three variations of the machine, with appropriate check boxes for when parts were ordered and when they were fabricated for production.

A most useful tool available to us was provided by a new Service manager and his right hand man. As we were working on the full production machine, we constantly received field feedback reports on the pilot unit(s). They were organized in such way that we were able to use their lists almost like a cook book. Their system was new to Toro and worked beautifully. There were design problems to be dealt with. They clearly established the priorities and provided the road maps for all the product lines. They were a perfect example of the way a service department should relate to engineering groups.

Through close coordination with manufacturing engineering (in Minneapolis), we decided that all components of all three units of the line were to be designed and documented simultaneously with all the production procedures. We practiced "concurrent engineering" long before the process was so named. Subassembly drawings were planned and drawn with find numbers to identify the various parts for that particular assembly station. We were told Toro drawing standards (based upon Control Data (???) standards) didn't allow mechanical subassemblies or parts lists printed on the drawings. We did it anyway. Partly, as result of our extremely accurate assembly drawings, Toro's award winning technical illustrator created the first service manual that used, almost exclusively, line drawings, instead of photographs. These service and parts manuals set a new standard for the industry.

The production lines were laid out and completely planned in Minneapolis. The appropriate mechanical subassembly drawings, with critical reference dimensions, were hung up as a reference at each assembly station. Finally, specific individuals, most knowledgeable of these units' function, were camped on the Windom production line for the first few days of startup to make certain that the individual assembly workers knew exactly what was expected. Windom management was very cooperative in supporting and assisting our education of the assembly staff.

As we were getting ready for production, the company went through restructuring. Startup and production commenced just after the start of tenure of a new Director of Engineering and Manufacturing for the Consumer Division. We gave him a very nice present.

As result of this effort, the three unit snow thrower line acheived the highest internal quality audit rating ever awarded a new consumer product line at Toro (96% or 97%). That year, the new line's quality rating was higher than Toro's bread and butter, the walk power mower lines. We were quite pleased to provide Toro's old timers with a lesson on how the process was supposed to work.

The following year, continuation design work by others was superb. This involved some re-mixing of the horsepower-width relationships and a very thorough tying up of loose ends, resolving typical field and production problems, plus a general "polishing" up of the whole three-unit line. This process was helped along in a very critical manner, by way of a total facelift of the whole line by Mario Fernandez and Bruce Rubin of the Fernandez-Rubin Industrial Design office. This included a brand new corporate logo and color scheme. This total process served to "lock in" and amplify Toro's successful entry into the big time snow market.

Following this, Fernandez and Rubin began a review and update of all Toro's product lines with their completely new (and still current) corporate logo and color scheme. Their prodigious efforts were crucial to the whole company. In fact, Toro's present color scheme, it's logo, and general graphical image themes, all originated by Fernandez and Rubin, remain much in evidence today.

Following the second year's production, the middle unit of the three unit snow thrower line was selected as No.1 with Consumer Reports. Much credit has to be given to the continuation engineers. Also, they had an absolute rock solid foundation from which to begin the second year's design modifications.

The next year, this was followed with Toro's extremely well engineered (by the same continuation engineering individuals) and highly profitable Snow Master single stage snow thrower line. The industrial design work on this line was also performed by the Fernandez and Rubin office. This combination of double and single stage snow products served to accomplish Toro's total domination of the snow markets within about three years. This was the equivalent of about three or four home runs in a row. Toro definitely won the "Snow" game. In fact, Toro rose from last place (almost non participant) in the Snow League to take the Snow Thrower World Series in about three years. This 3-4 year series of projects was a dynamic lesson in the way the new product development process should work. Toro continues to dominate the snow market to this day (i.e. the "lawn mower company that doesn't belong in snow" - CW of most of Toro's middle management at the time).

The original "Snow Mill" two-stage snow thrower line was, to that point, Toro’s first truly successful attempt at original design and production of a consumer product much more complicated than a lawn mower. This "Snow Mill" line was, without question, the genuine "Grandfather" line to all the subsequent large snow entries by Toro. Even though snow is now a small part of Toro's total sales, it definitely did its job in helping to establish Toro as the full line Lawn and Garden top flight performer that it has become. In addition, its "halo" effect most certainly has benefited the commercial (golf course etc.) lines. We are quite pleased that we were able to play a very critical part in helping Toro to become such a dominant player in Lawn and Garden equipment.

Finally, Toro's original establishment at the top of the snow business is mainly due to a number of people who rolled up their sleeves and did the work, or contributed heavily by their positive interest, encouragement, and involvement. These are Bob Mittelstadt, Dave Nordberg and his Kitchen Gang, Jack Witherby, Earl Beaver and the shop, Ralph Endress, Dale Atkinson, Phil Toms, Lyle Fahning, Ron Bergerson, Jim Jacobs, Ross Nelson, Jim Swindal, Henry Tetzlaff, Jerry Patrin, Mario Fernandez, Bruce Rubin, Claude Morris, Ken Melrose, Dave Good, Elliot Mjolsness, Ed Wingate, David Lilly, Al Conover, Finn Larson, Bob Ouimette, and the whole Windom facility. The project engineer for this original multi-unit two-stage line(s) was John Berner.

TORO'S

POWER CURVE CONFIGURATION (Project Engineer)

TORO'S

POWER CURVE CONFIGURATION (Project Engineer)

While still an employee at Toro, Berner originated the concept of curved rubber blades on single-stage snow throwers, now common throughout the industry. This concept of what came to be known as the "Power Curve Rotor" dramatically advanced the performance and commercial viability of single-stage snow throwers by shaping the rotor to maximize the efficiency of energy transfer from the rotor blades to the snow stream.

This project was initiated in a three person discussion between David Lilly, Bob Mittelstadt and John Berner. David Lilly, Toro's Chairman, suggested "Why don't you guys come up with a way to throw snow in a manner similar to a person shoveling? Shouldn't this be the most efficient way to do it because there is minimal impact?" After giving this some thought, Toro's original "Power Curve" configuration was created by Berner. This was the direct result of the analysis to move snow with minimum energy loss due to impact, or pulse, to the snow particle - - i.e. like David Lilly's snow shovel.

Through careful analysis, it was determined this would be accomplished best if the snow particle velocity starts out slowly, then increases continuously to a maximum just as it is ejected from the auger/impeller combination. However, because of the standard configuration of a single-stage snow thrower, this could occur only for the particles at the very outside edge of the snow cut path. We constructed and tested this configuration quite handily with some of the rubber paddle material we had earlier used for a flat paddle snow thrower configuration. The performance improvement was dramatic.

After sitting on the shelf for quite a few years, the final production version of this concept was exceptionally well executed by Toro's consumer engineering group. The same group incorporated a major improvement over our original version with their means of connecting the rubber blade to the rotor shaft. (This page revised 6/5/16). Also, by adding a tapered chute, they minimized additional frictional losses between the chute and the snow stream. The curved rotor development made single-stage snow throwers more efficient at throwing snow, allowing for them to replace many of the more dangerous and expensive two-stage snow blowers.

SUGGESTED LIST OF PROJECT SCHEDULE CHECKPOINTS

APPLICATIONS RESEARCH, INC.

4927 St. Croix Avenue, Golden Valley, MN 55422

For more information, call (763) 521-0217